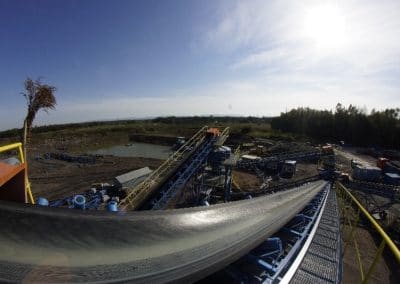

Opencast mining plant

WHAT DO WE OFFER

Sand from 0-2mm

Crushed aggregate

gravel 2-8mm

gravel 8-16mm

gravel 16-31,5mm

gravel mix 0-63mm

production

exploitation of the deposit

In order to achieve optimal use of natural aggregate „Brzeszcze-Buczaki”, applied modern mining machine – dredge floating dredgers. Gravel extraction process is carried out scoops from under the water, and then the dredger is transported by conveyors floating route and the stationary processing plant.

Aggregate mechanical processing technology

The technological scheme of the plant contains one technological line. It is a technological line of broken fraction with products in grain classes 2-8 mm and 8-16 mm, 16-31.5 and sand 0-2 mm.

- Used for crushing jaw crusher, and a cone crusher.

- Dewatering sand fraction is a dehydrator.

- Used for the transport belt conveyors.

- The final classification nodes use 2 and 2.5 deck screens equipped with polyurethane sieves. The screens have a water installation (wet screens) powered by a Meta pump.

Determination of grain composition by screening

PN-EN 12620+A1: 2010 Aggregates for concrete

PN-EN 1342+A1: 2010 Aggregates for unbound and hydraulically bound materials used in buildings and constructions

HYDROSTAL Sp. z o.o.

OPEN-CAST MINING PLANT BRZESZCZE

32-620 Brzeszcze,

str. Ofiar Oświęcimia 78

tel. +48 785 888 717

zwirownia@hydrostal.pl

https://hydrostal.pl/en/gravel-mine